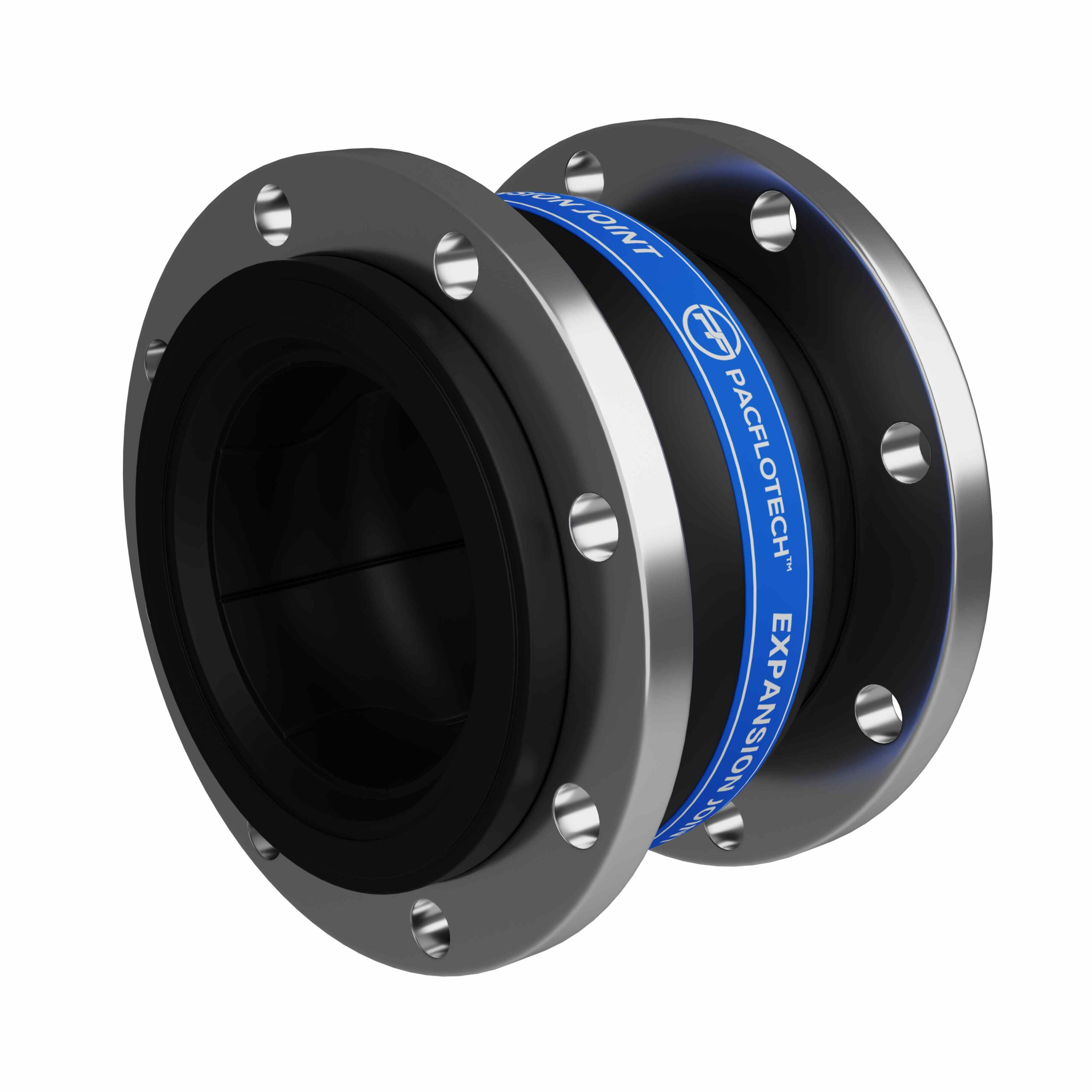

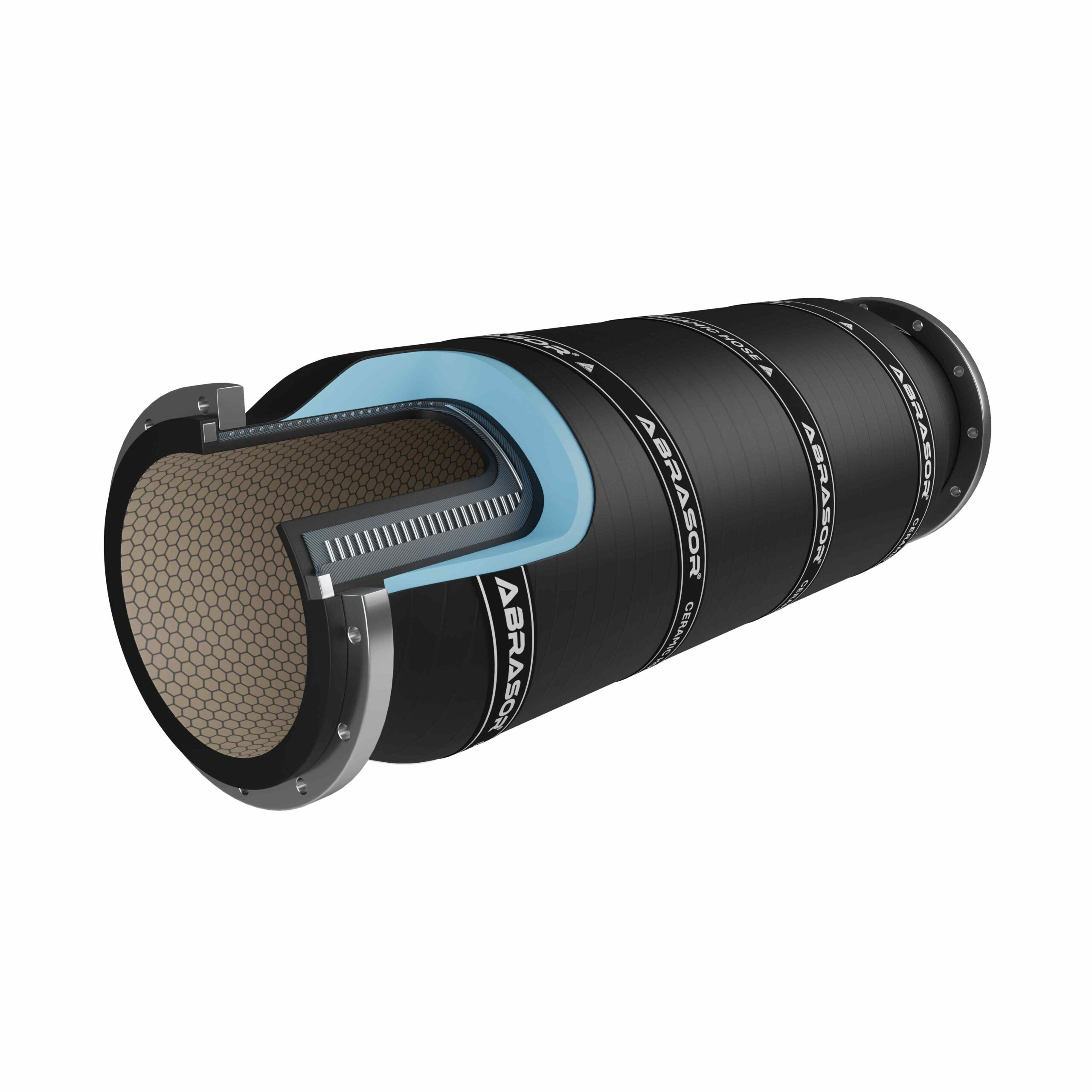

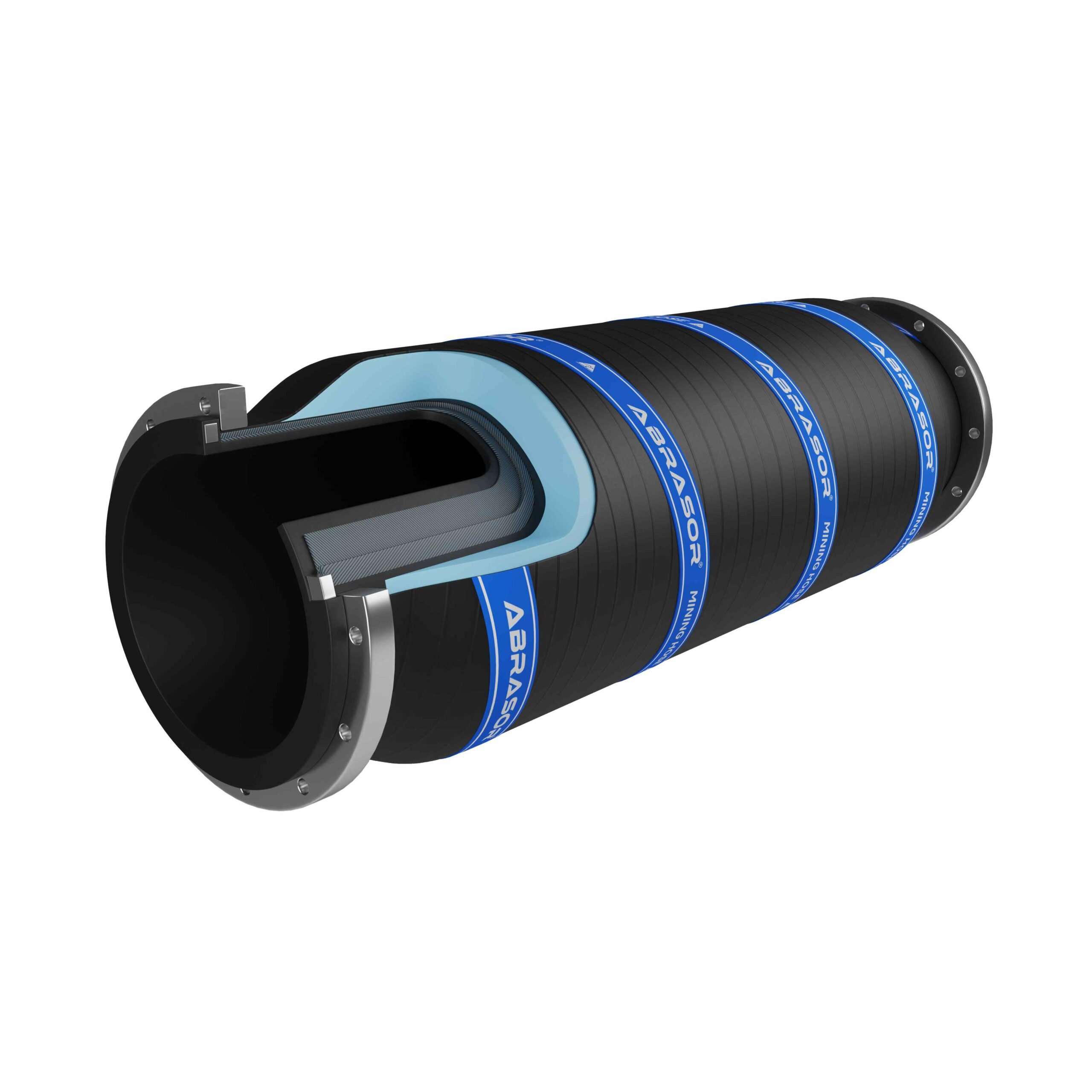

Abrasor® X50-Series Muff Coupling Hose is designed for compatibility with our split muff couplings. Featuring one or both ends plain cut, these hoses can be easily trimmed to length on-site, providing a perfect fit for your specific requirements. Lined as standard with our exclusive Abrasatech® tube liner, our muff coupling hose offer industry leading abrasion loss numbers, setting us apart from the many lower quality imported variants in the market.

The Abrasor® X50-Series is a fully integrated suction and delivery muff coupling hose featuring a spring steel wire helix and textile reinforced walls to withstand harsh working environments under full vacuum. Each hose is custom made to suit your exact application, ensuring the longest lifespan and reducing costly downtime.

Proudly manufactured in Australia, Abrasor® is trusted by leading operators worldwide who demand performance, flexibility, and endurance from every metre of hose. We have the largest hand-made hose manufacturing facility in Australia, ensuring we have the capacity to meet your requirements no matter how big or small. Our extensive range of stocked liners allows our muff coupling hose to be made suitable for medias or slurry containing water, chemicals, acids, hydrocarbons, food grade products and high temp solutions.