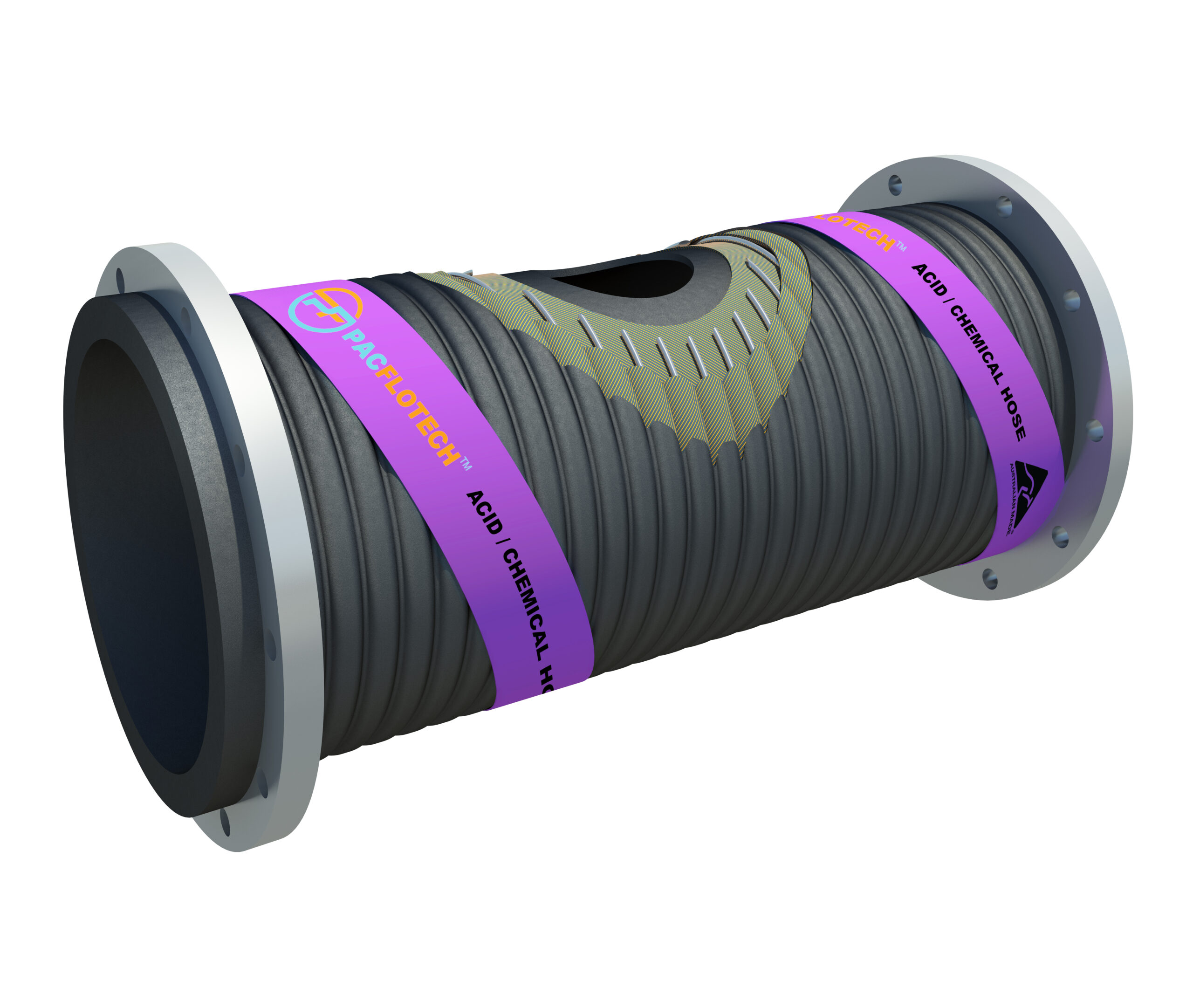

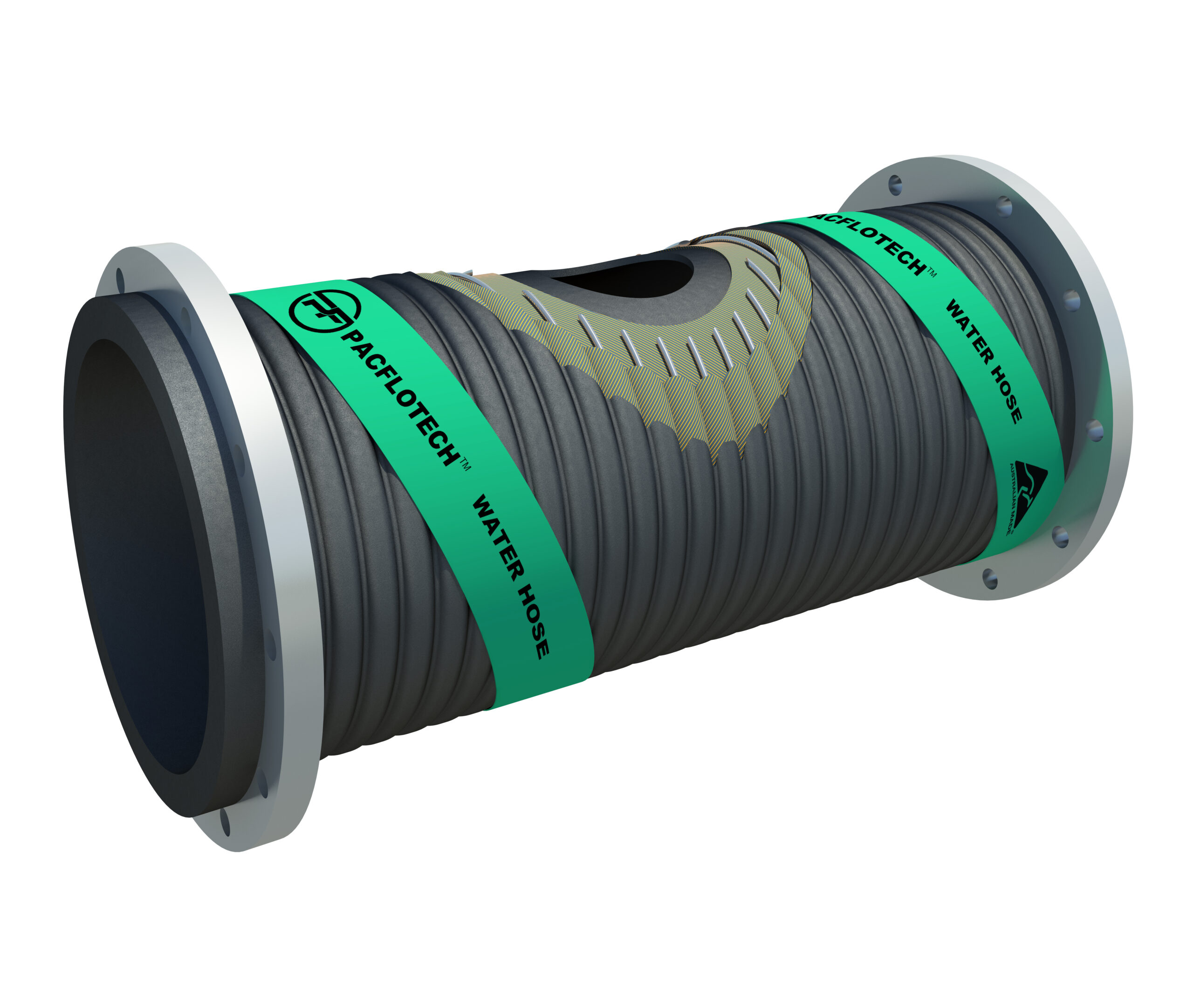

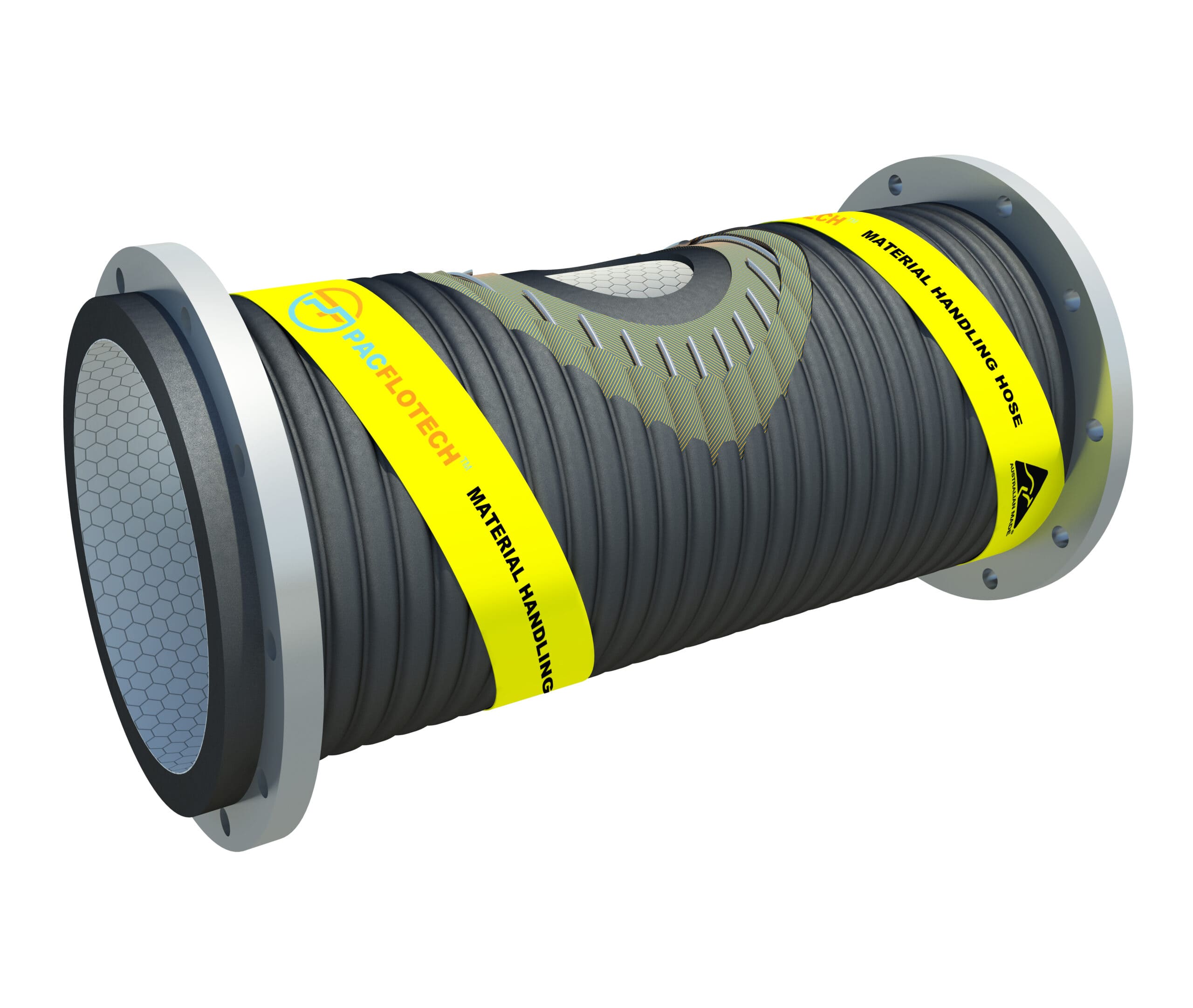

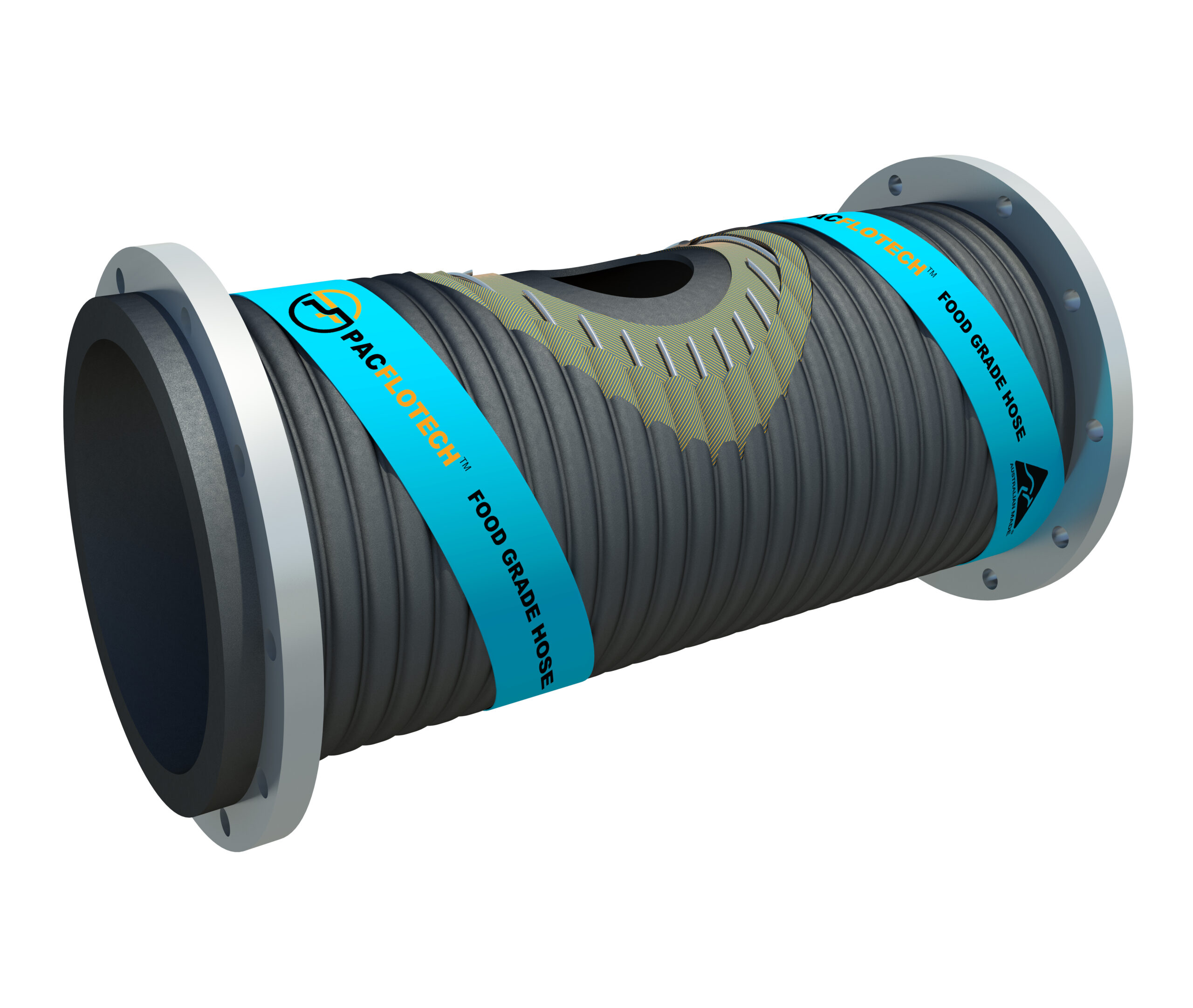

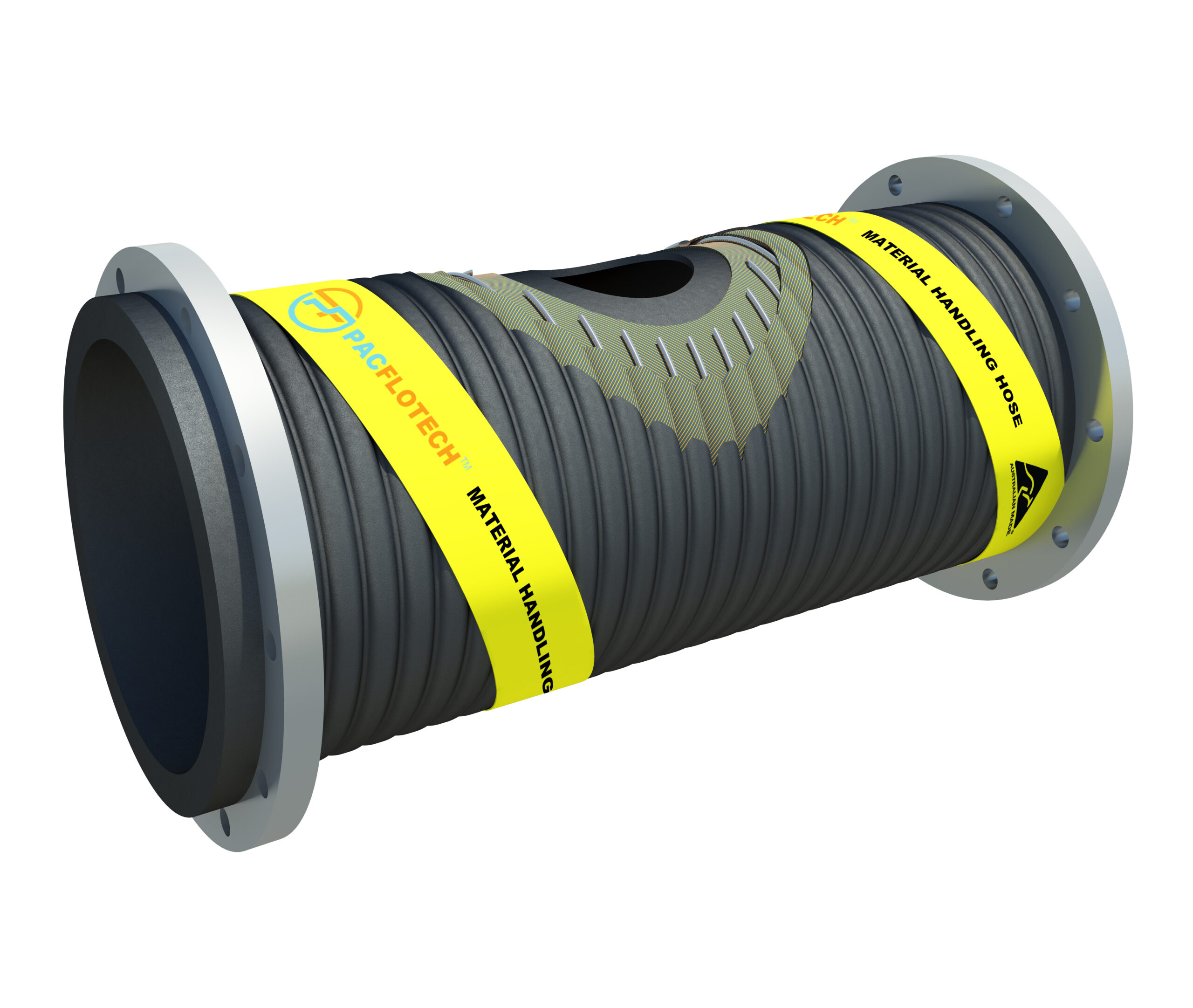

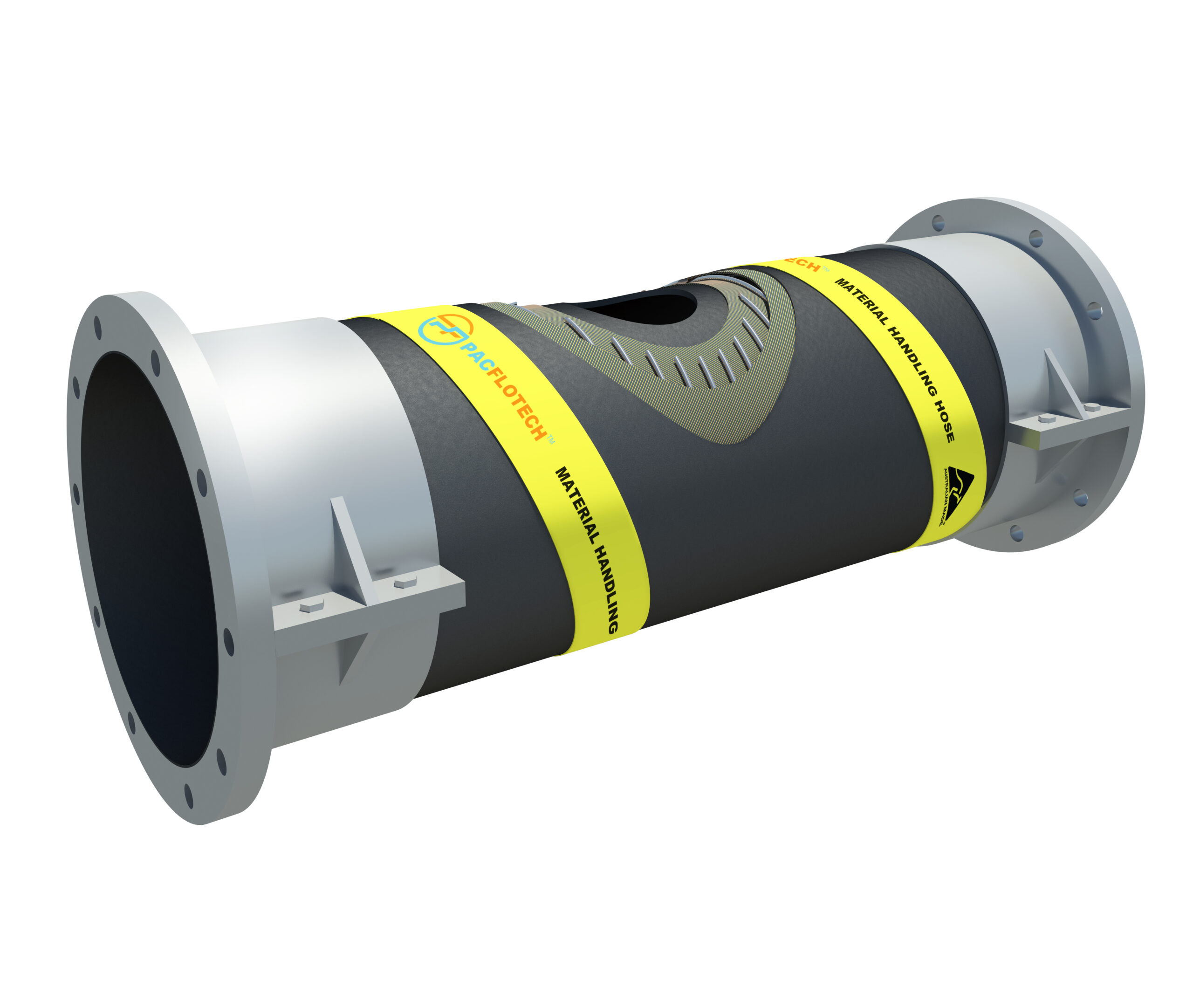

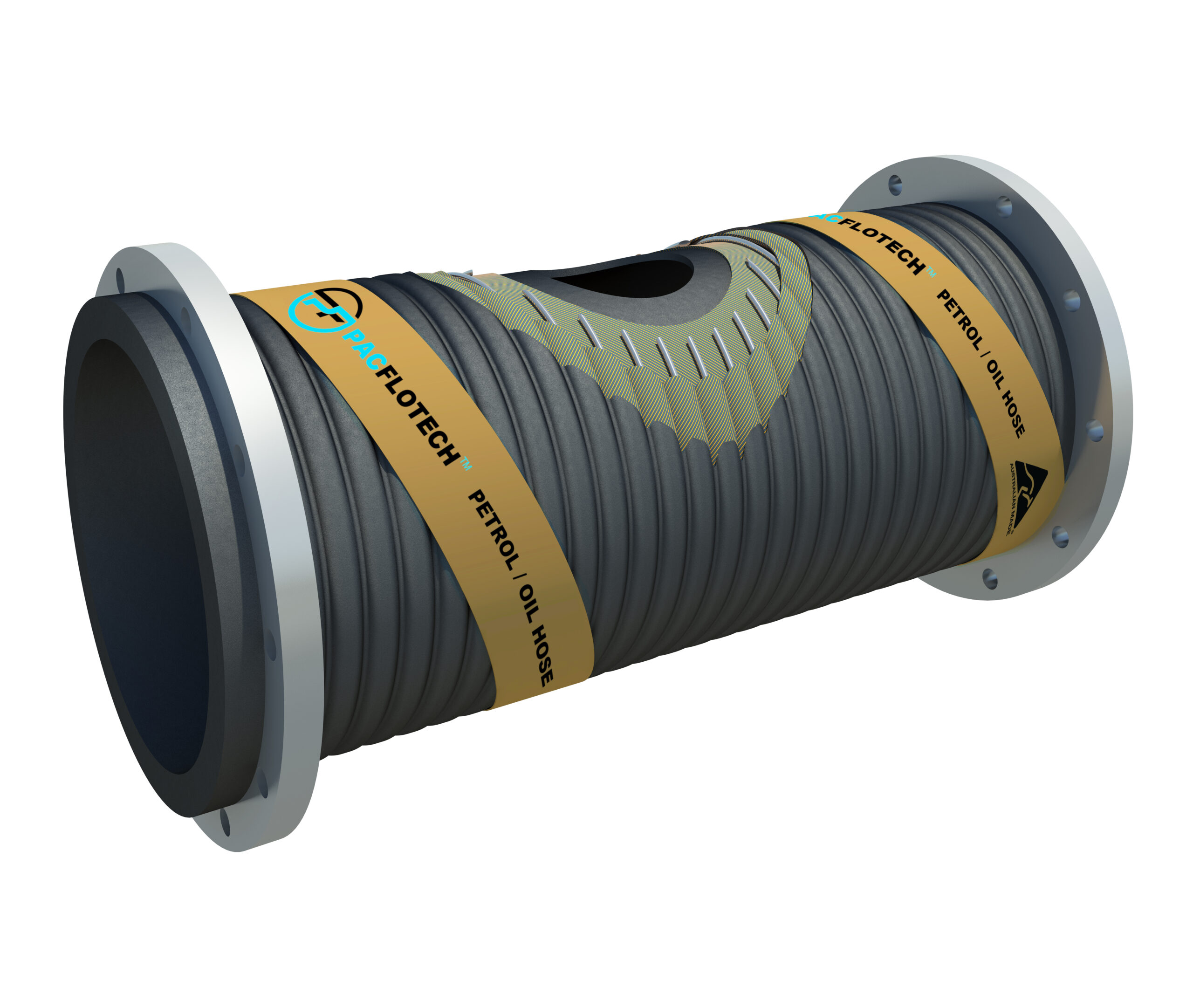

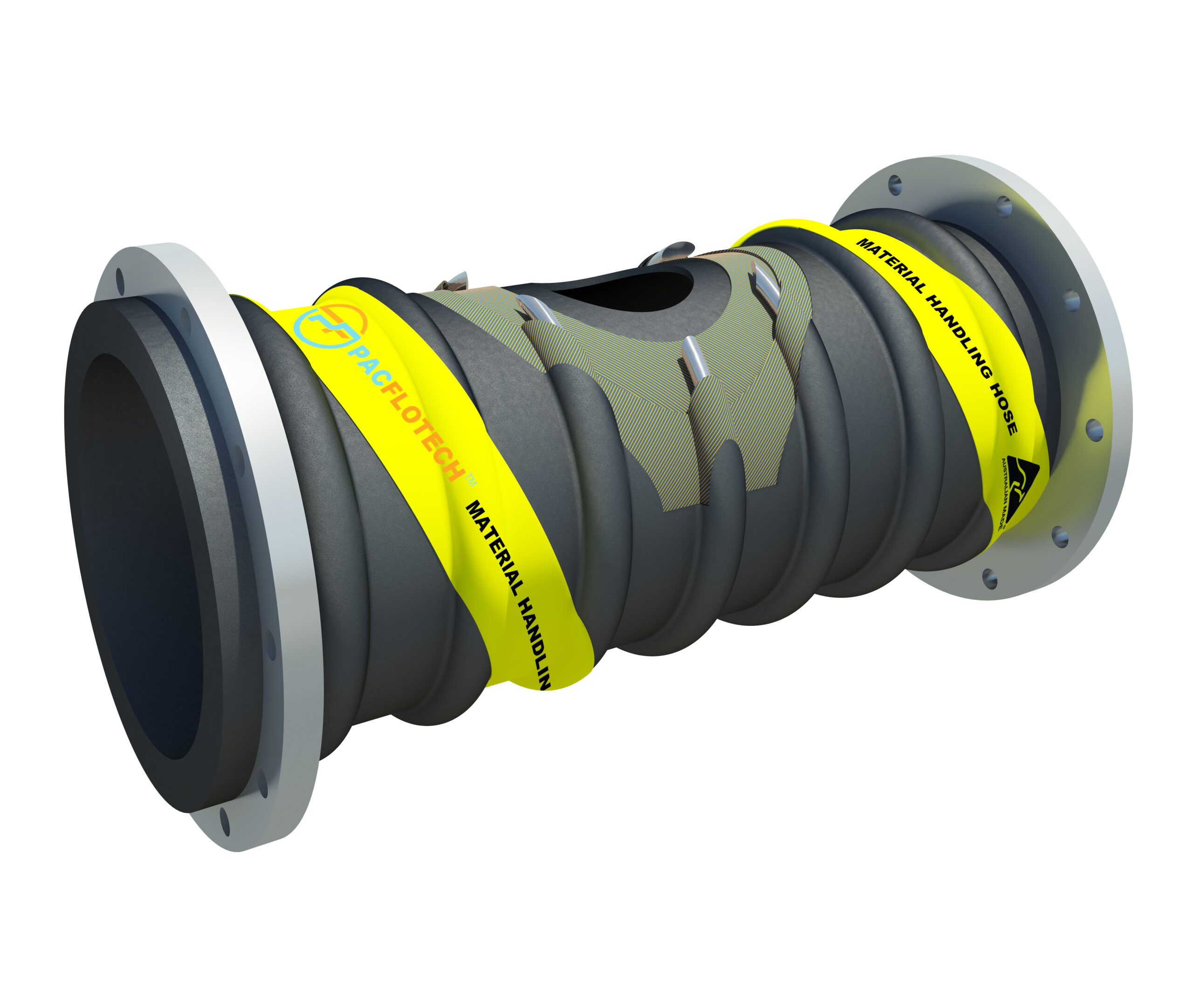

Muff Coupling Hose

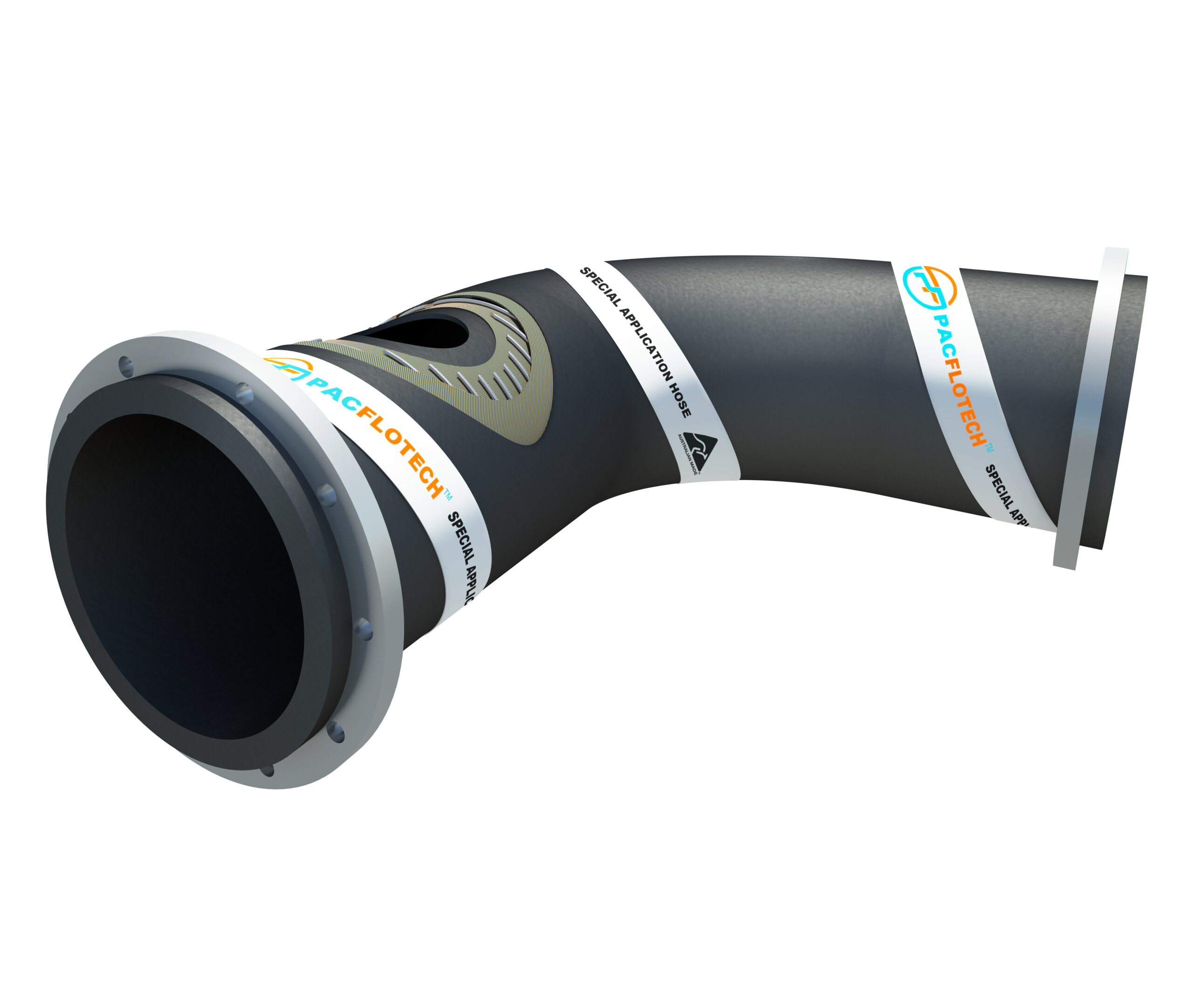

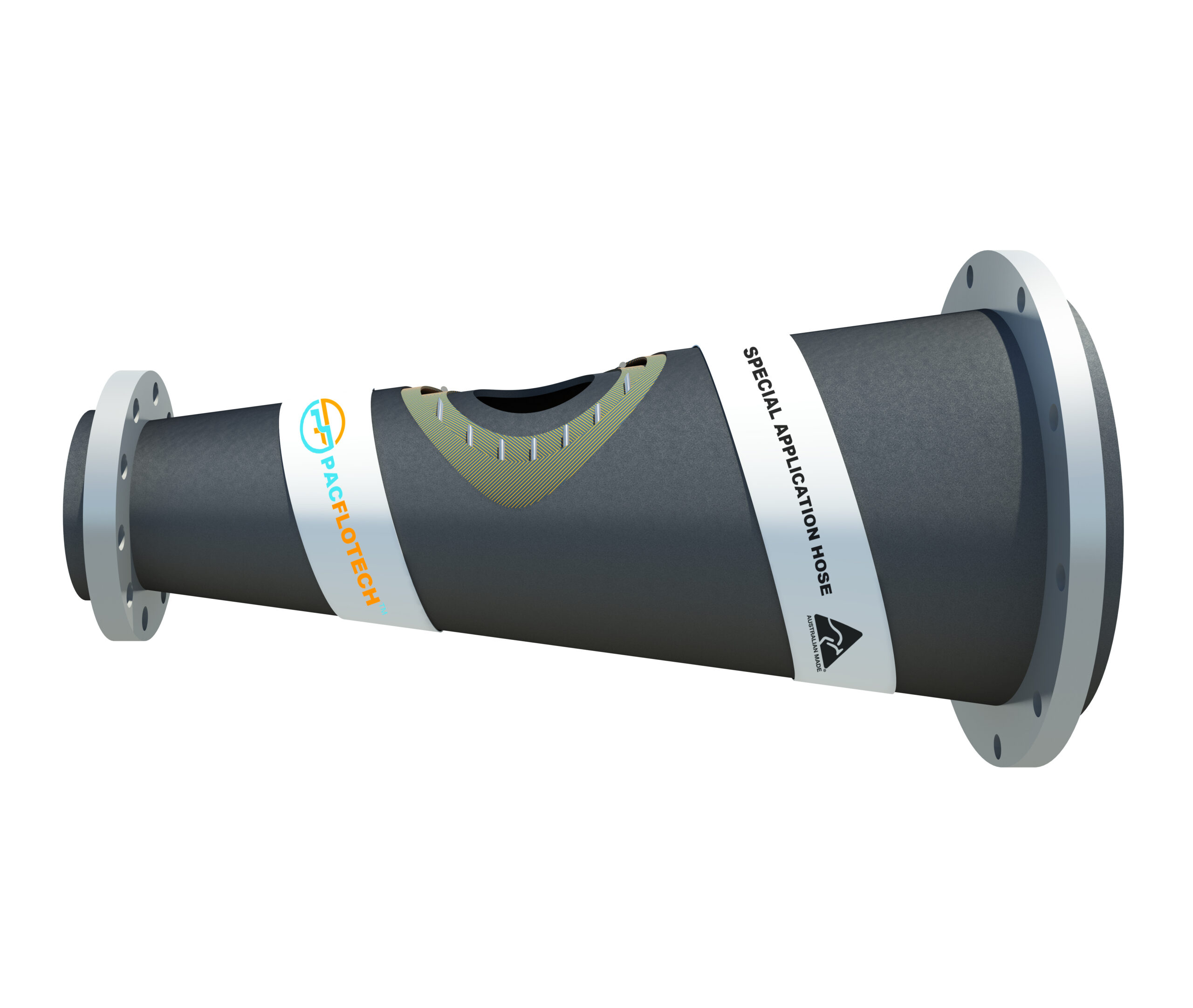

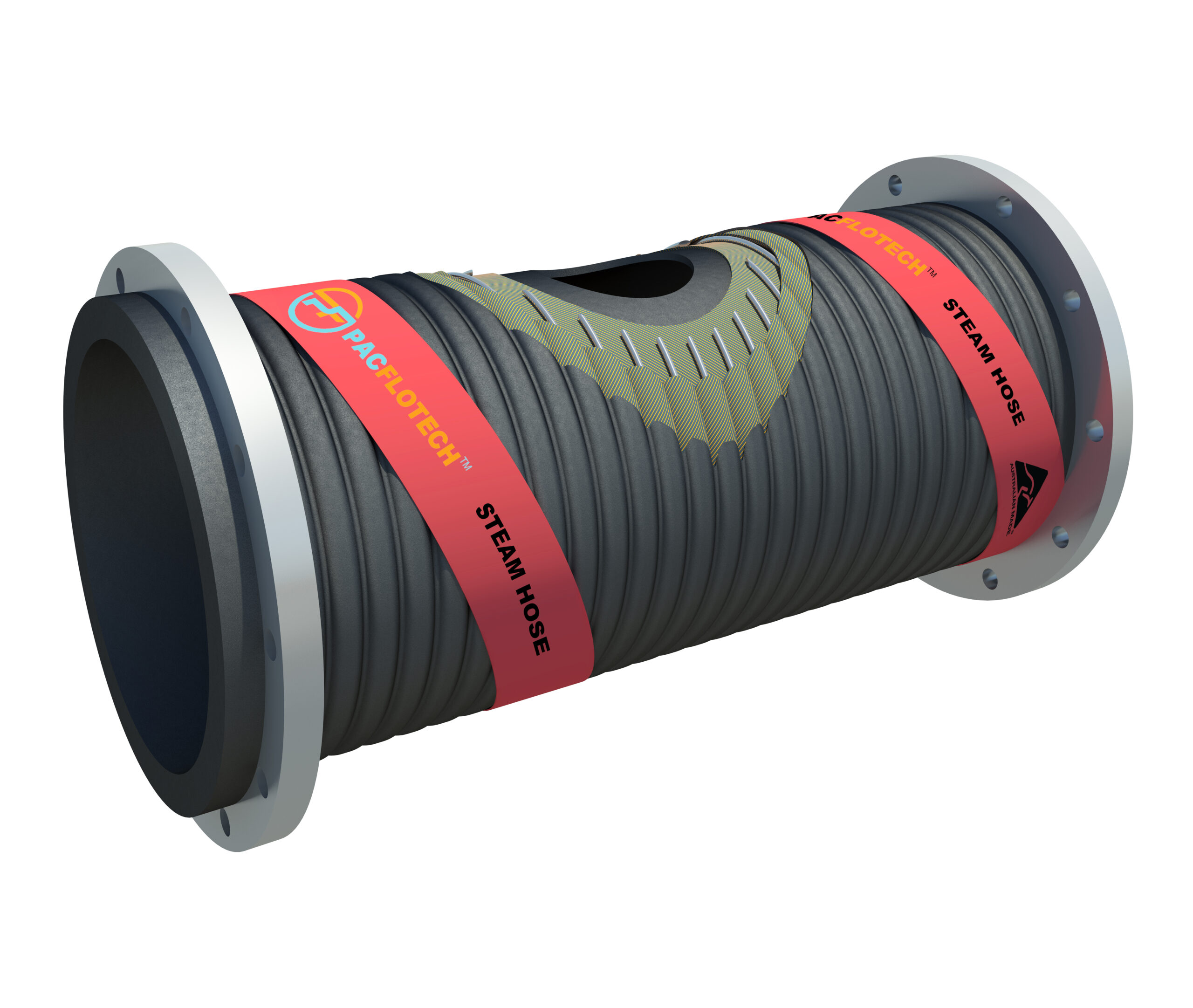

Pacific Flow Technology’s hard walled mining hose is universally designed for use with split muff couplings, ensuring a reliable, secure connection. Delivering exceptional durability and performance, our muff coupling hose is an essential choice for mining operations and other demanding industries.

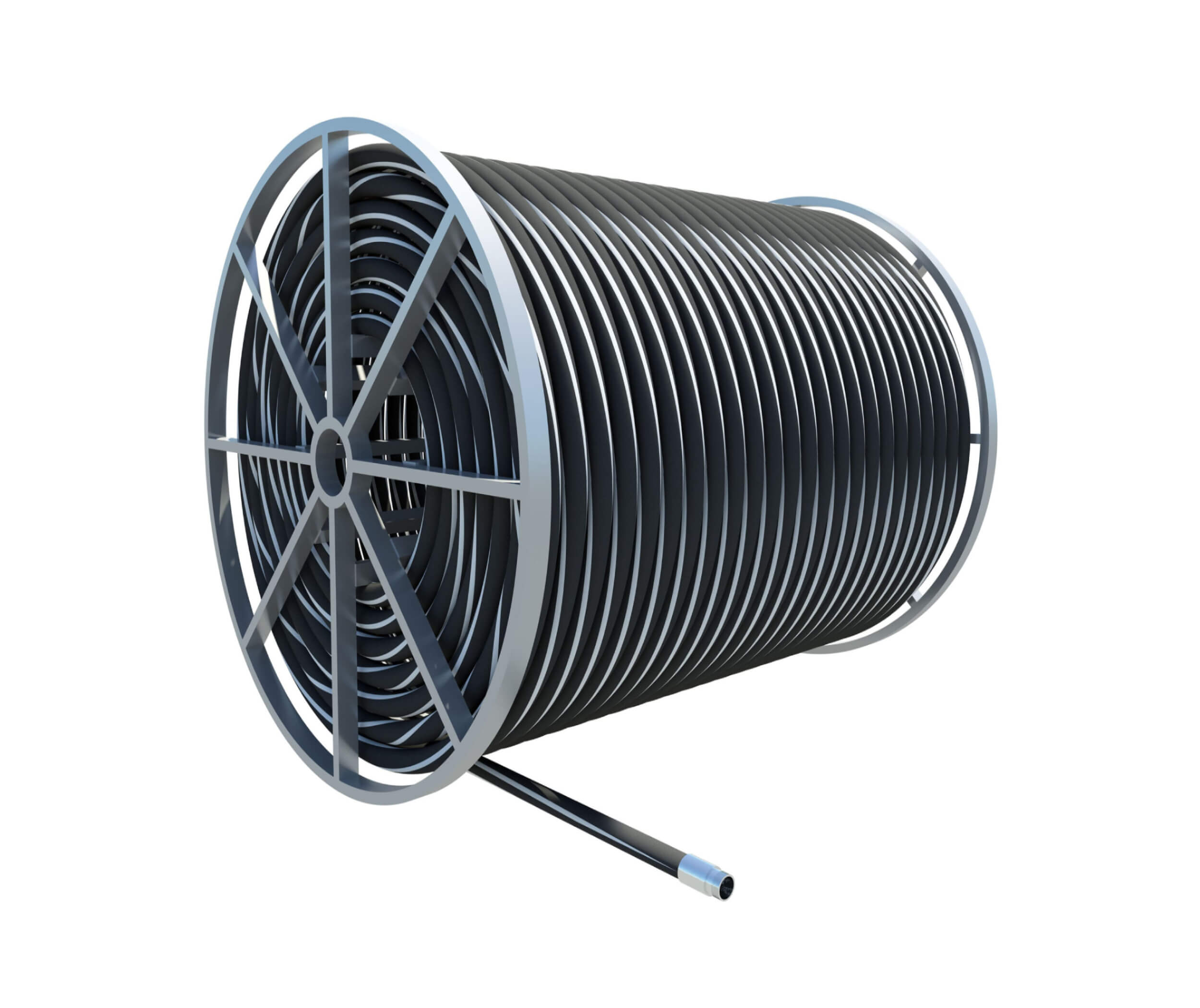

With plain-cut ends on one or both sides, this versatile hose can be cut to precise lengths on site, ensuring an exact fit for your specific application. This adaptability minimises downtime and improves operational efficiency. Our mining hose for muff coupling use is also equipped with our exclusive abrasion resistant liner, providing superior durability and longevity that outperforms generic imported alternatives. Made for the toughest conditions, it delivers consistent performance, reduced maintenance costs and extended service life, making it a dependable solution for the mining and industrial sectors.

A Trusted Provider

Pacific Flow Technology has earned a reputation as a trusted provider of high-quality muff coupling hose products. With over 100 years of combined experience in rubber hose manufacturing, you can rely on us to deliver durable solutions that meet the rigorous demands of the mining industry. We proudly operate one of Australia’s largest handmade hose facilities, allowing us to create custom designs of any size or complexity. We’re dedicated to delivering tailored solutions backed by unparalleled technical support and expertise.