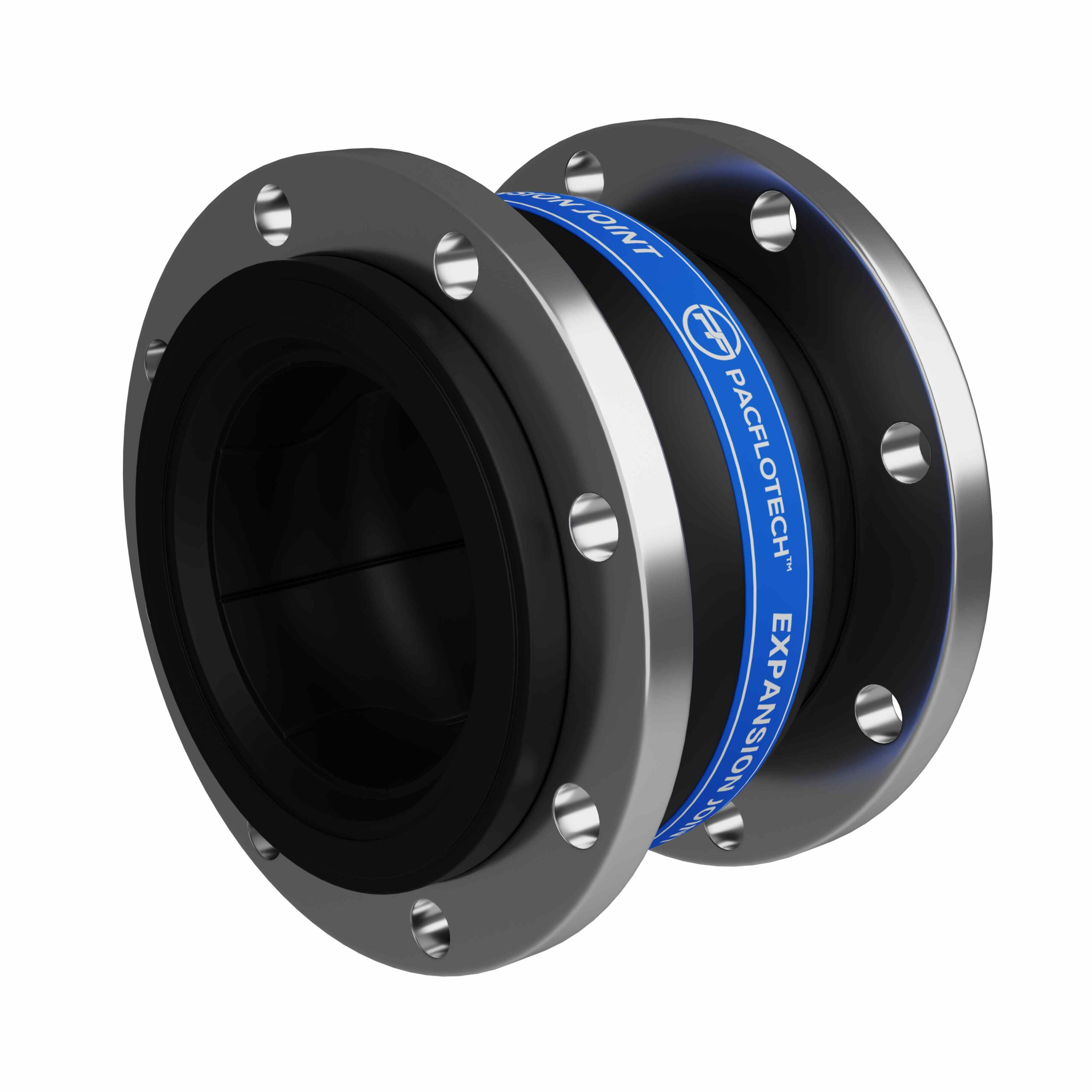

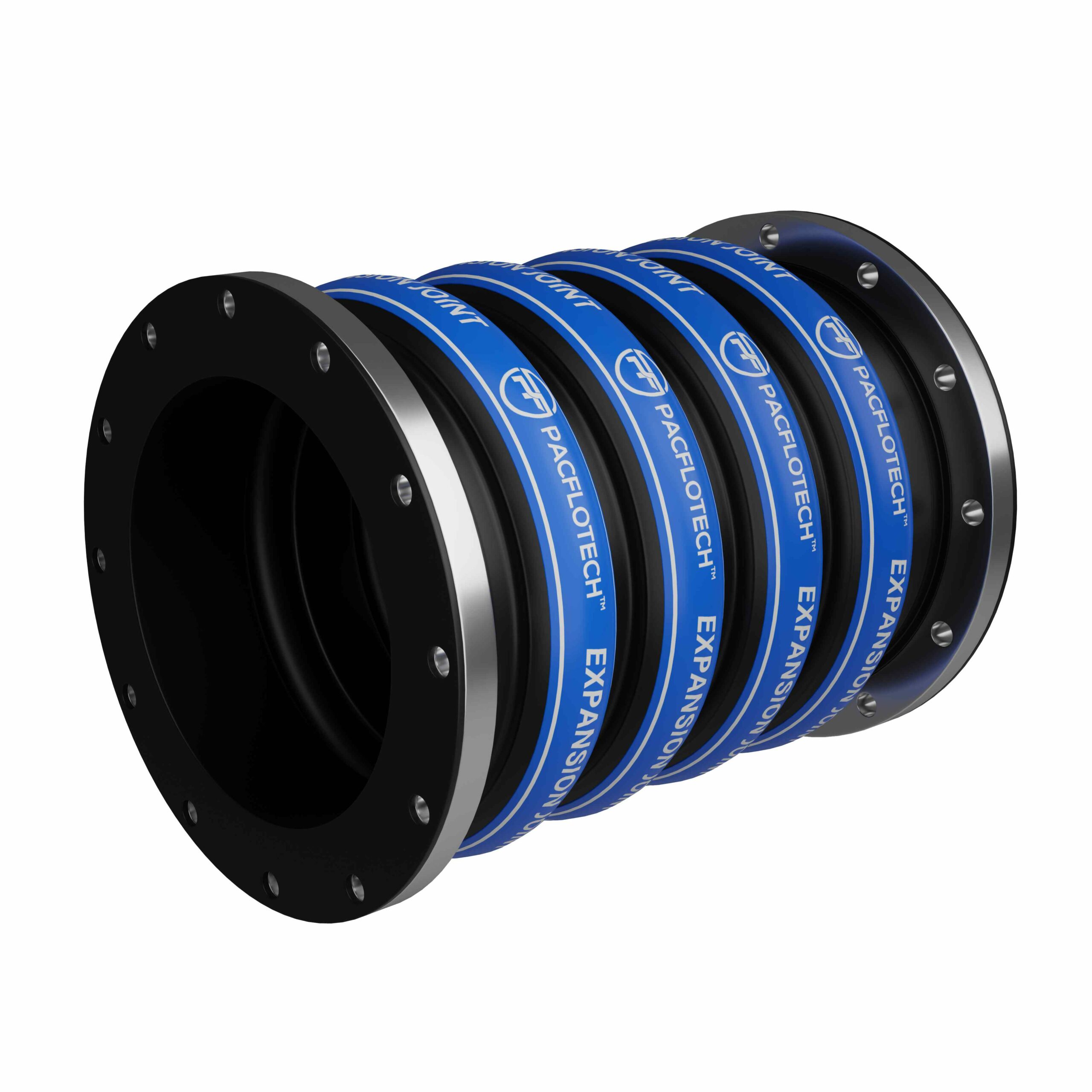

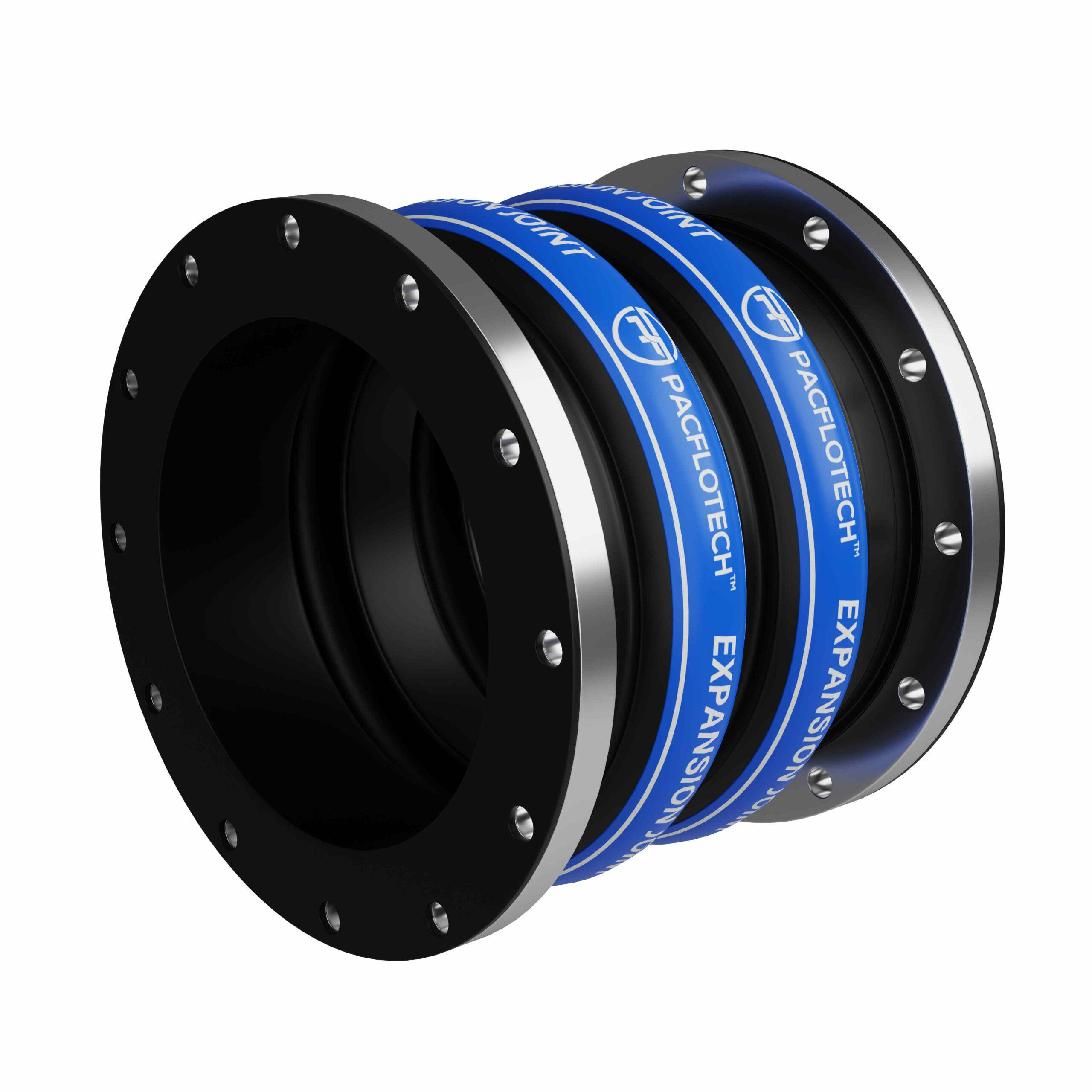

Pacflotech® XM20 Series Double Arch Moulded Rubber Expansion Joints are constructed to reduce or eliminate noise, vibration, misalignment, offset, and thermal expansion in piping applications. The double arch spherical bellow design allows for greater compression, deflection and elongation over a single arch design All of our double sphere moulded rubber bellows can be customised with vacuum rings, control rods and arch fillers, making them suitable for many applications.

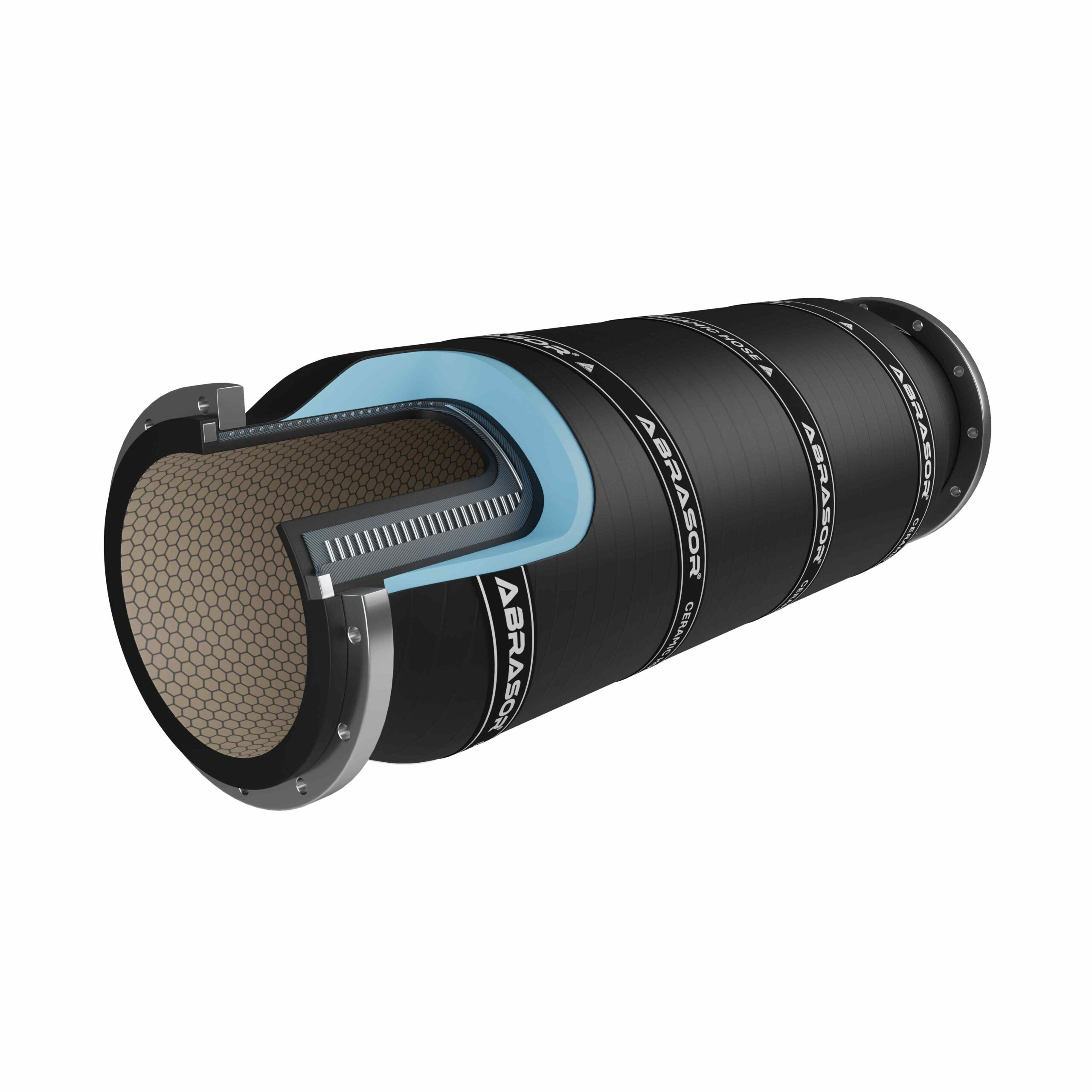

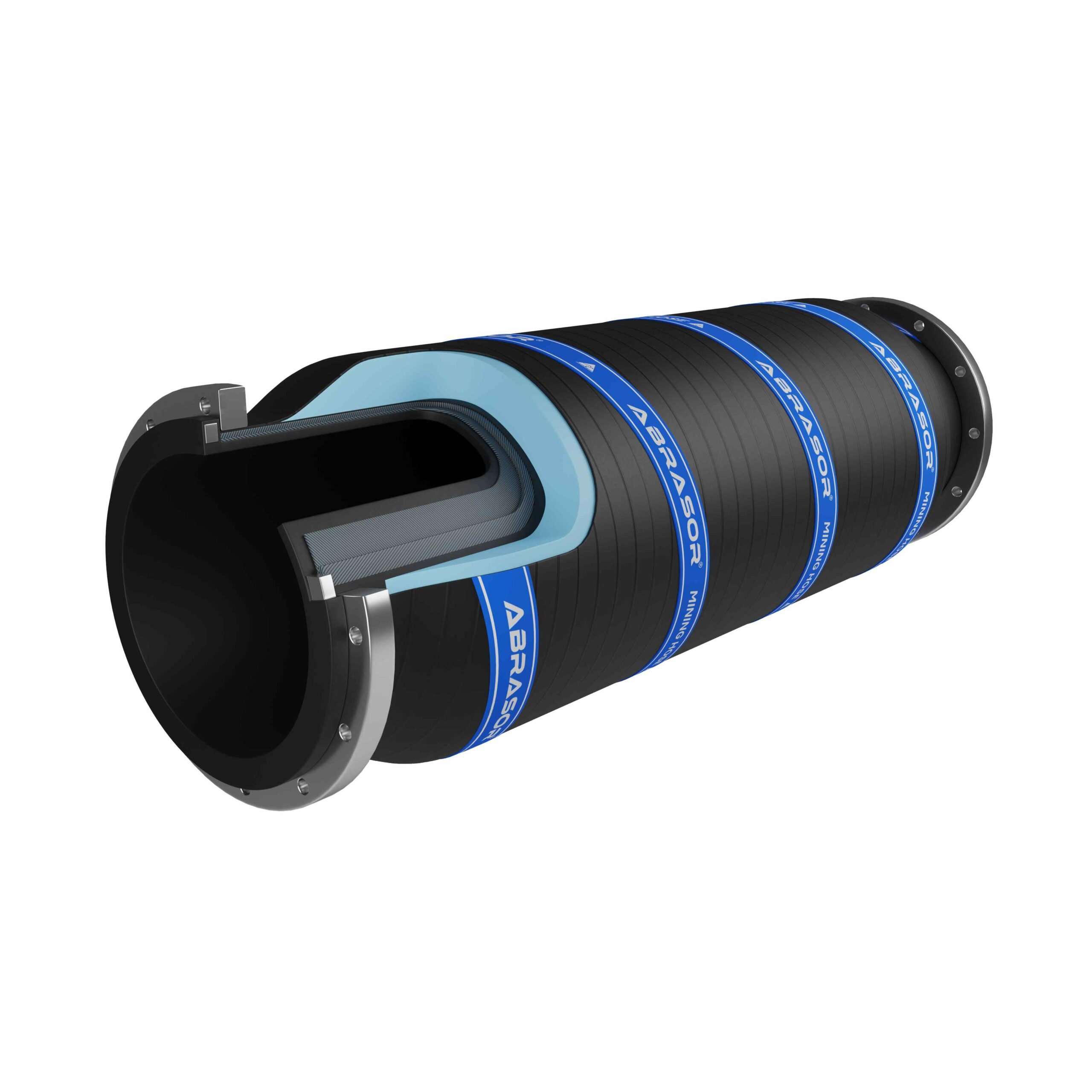

The XM20 series is precision moulded, featuring textile reinforced walls and the option for vacuum rings in suction applications. Due to our extensive range of liners, our double sphere moulded rubber bellows can also be made suitable for medias or slurry containing water, chemicals, acids, petroleum, and high temp solutions.

With over 100 years of combined expertise in hose manufacturing and piping solutions, you can trust our ability to service your double arch moulded flex joint needs. Our solutions are custom made and tailored to your exact specifications, minimising the risk of failure, and reducing costly downtime.