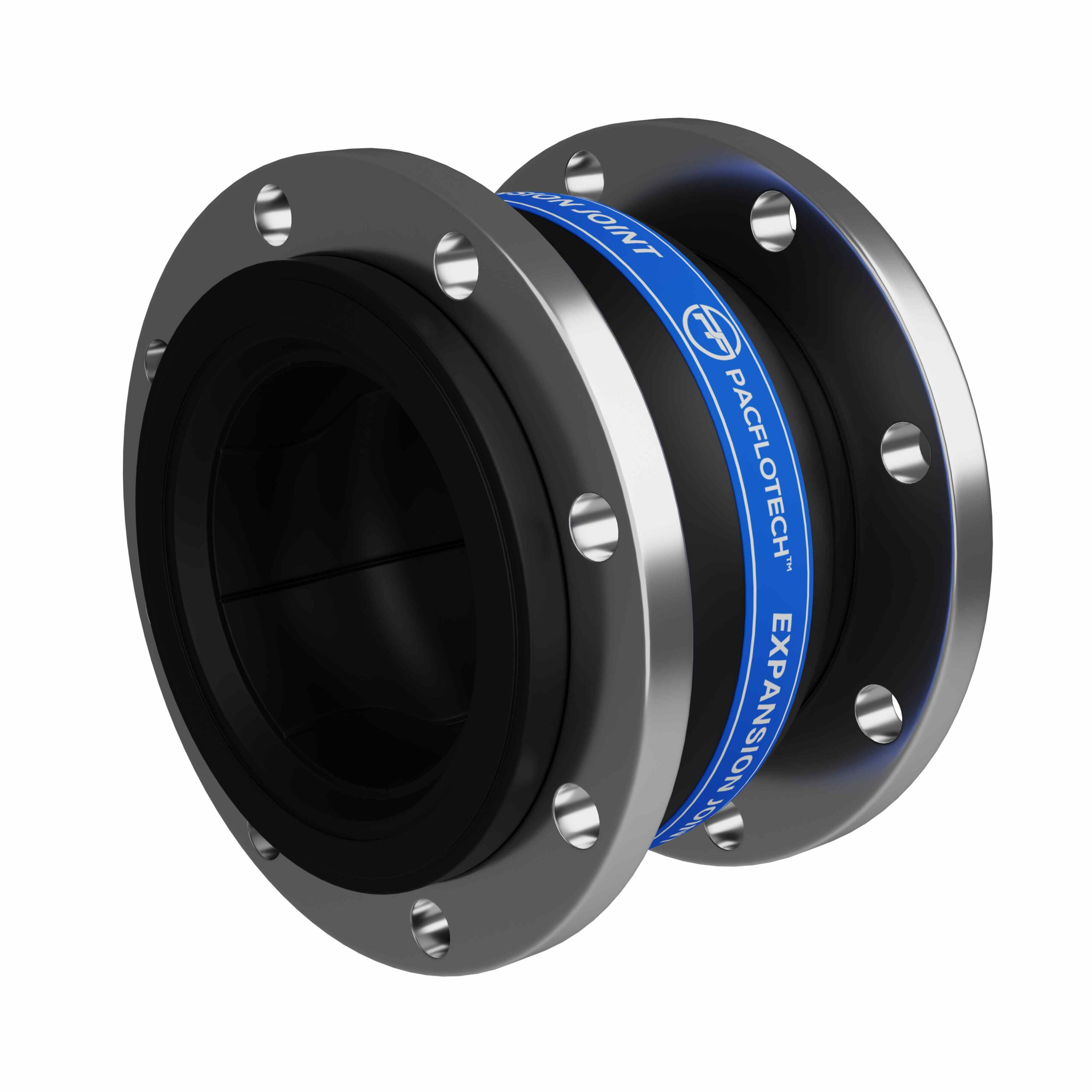

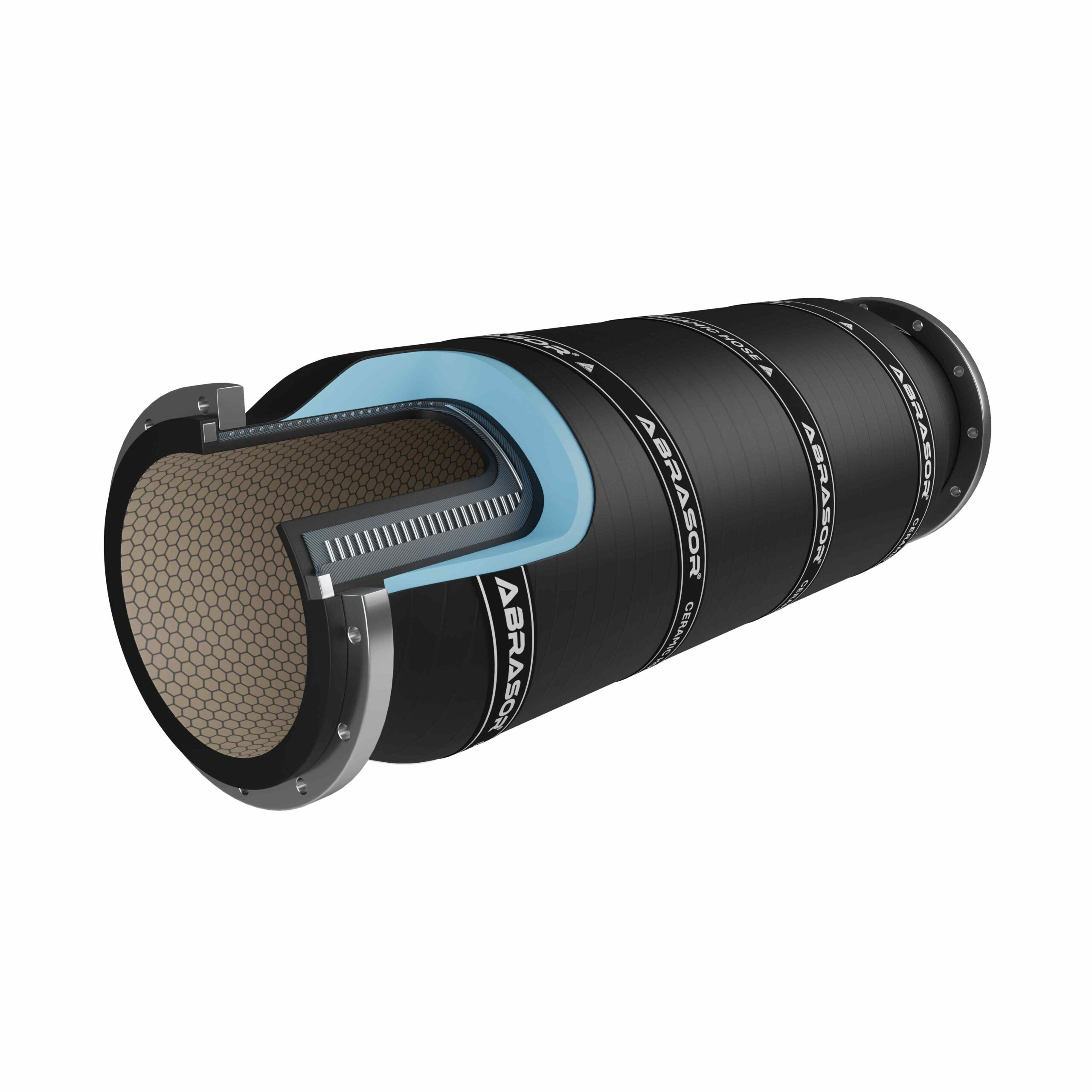

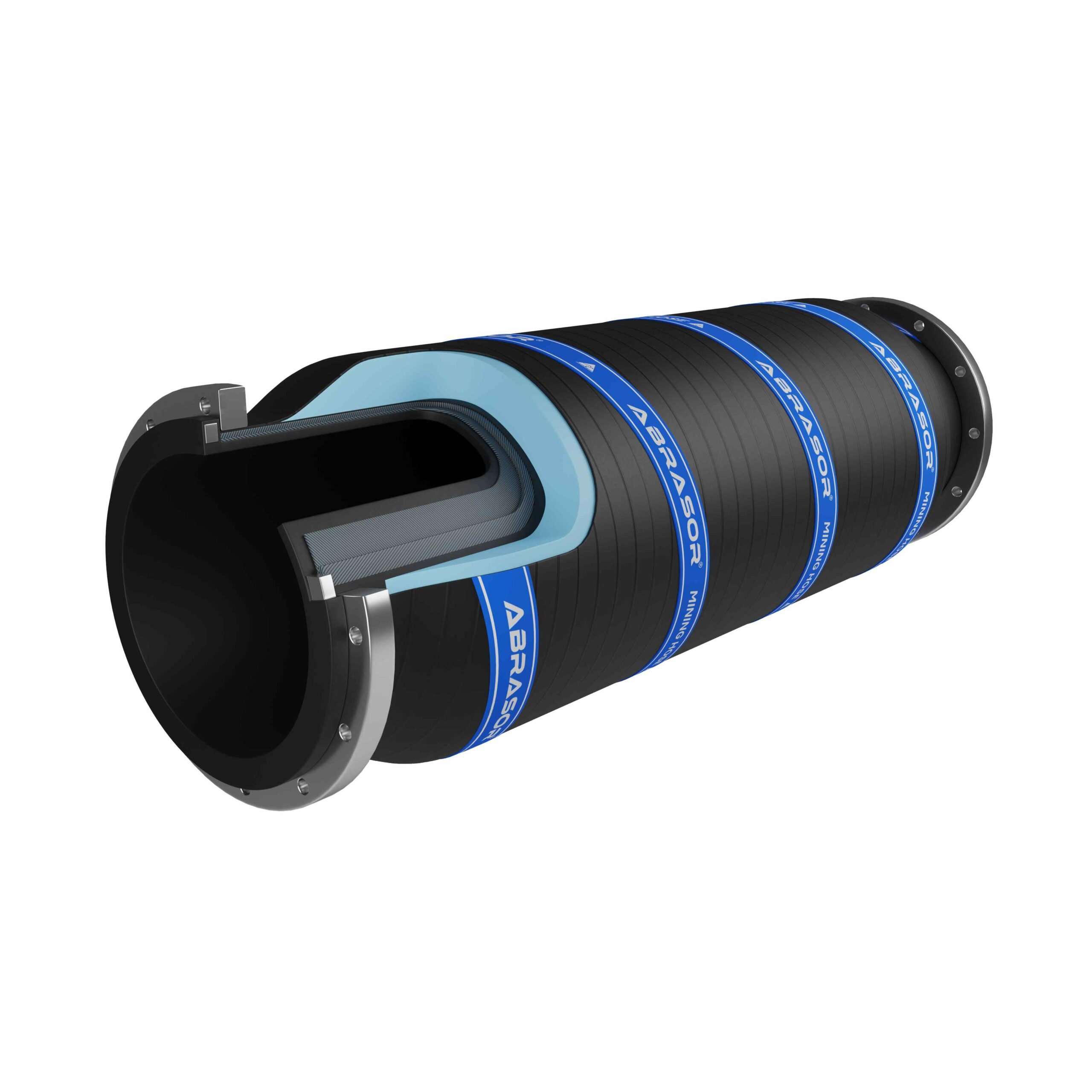

Abrasor® XC20-Series Pre-Formed Ceramic Hose Bend is built to handle the harshest slurry environments where both durability and flexibility are critical. Designed to achieve tighter radius bends than standard straight-length hoses, accommodating space constraints without compromising flow efficiency. Abrasor® ceramic Hose merges the superior cut, scratch, and tear resistance of ceramic with the impact absorption and flexibility of rubber delivering the ultimate hose solution for handling the most aggressive slurry applications.

The Abrasor® XC20-Series is a fully integrated suction and delivery ceramic hose bend, featuring a spring steel wire helix and textile reinforced walls to withstand high pressures and harsh working environments under full vacuum. Alumina tiles are hot vulcanized into the hose, ensuring maximum bond and penetration through the tile gaps. Hexagonal tiles maximise the bonding surface area, reducing dislodgement of tiles, and increasing wear life.

Proudly custom manufactured in Australia, Abrasor® is trusted by leading operators worldwide who demand performance, flexibility, and endurance from every metre of hose. We have the largest hand-made hose manufacturing facility in Australia, and along with our extensive range of stocked materials we can ensure we have the capacity to meet your requirements no matter how big or small.